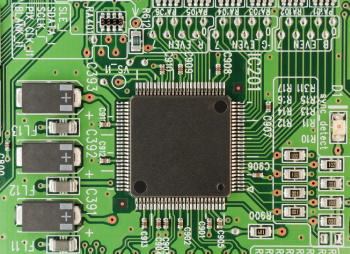

Electronics

Description of Industry

Electronics is perceived by many as an unlikely industry to experience odor issues. However, this is not the case. Odor from electronics may be indicative of excessive or unsafe environmental exposure during manufacture or shipping. It may also indicate a manufacturing defect, for example circuit board construction. Components such as adhesives, labels, and printing, may become odorous under certain conditions such as elevated temperatures. VAC identifies potential off-odor issues and provides proactive recommendations.

Applicable Services

What we do

By developing aroma profiles for your end products, you will have aroma and chemical baseline standards defined. These profiles can be used to compare and contrast to competitor products demonstrating your deficiencies or advantages for decision making. When a customer complaint occurs you will avoid the time consuming work of determining of what is considered the standard aroma profile and can concentrate on the difference in the complaint profile vs. an existing aroma profile. We are in the business of helping our clients reduce risks related to odor and educate our clients on the benefits of using proactive odor control measures including aroma baseline analysis.

When odor is perceived people panic. Whether there is a toxicity issue or not, and most of the time there is not, odor brings about unwanted distractions and risk to your reputation. Most of the time this occurs due to the unknowns involved. Any off-odor can impact substantially your bottom line without immediate intervention. VAC can help reduce your risk from off-odors affecting your products and help resolve problems in the most expedient manner.

Odor Analysis GC-MS/O

Gas chromatography-mass spectrometry/olfactometry provides the very best technique to quickly resolve off-odor issues. This method requires a trained odor judge to sniff GC effluent and rate odor character and intensity. This information is coupled by retention time automatically via software to GC-MS chromatogram data to allow for rapid odor identification. Our sensory and analytical team have more than 20 years experience with odor, analytical, and organic chemistry, and sensory analysis. Read more about our GC-MS/O Odor Analysis service by clicking HERE.

Odor Baseline Establishment

Baseline GC-MS/O measurements have proved extremely helpful to our clients because they establish the aroma and chemical profile of a product considered good. When odor problems arise new GC-MS/O analyses can rapidly determine what chemical changes occurred compared with a product considered good to allow for production process examination and off odor mitigation. For more on this service click HERE.

Odor Investigation

We utilize the most advanced scientific techniques and instruments currently available to detect and measure volatile chemicals responsible for odor. We utilize gas chromatography-mass spectrometry/ olfactometry to quickly determine what retention index values from a chromatogram correspond with odor. This capability dramatically improves our capability to identify trace level chemicals responsible for off-odors.

New Product Development Aroma Support

To ensure new products exhibit desired aroma character and intensity, we employ spot-on sensory assessment, extraction methods and analytical analysis. Sensory includes quantitative descriptive analysis to ensure the attributes measured match those desired. Extraction methods depend on the nature of the material. Dynamic headspace extraction works for many products however specialized techniques such as sir bar sorptive extraction and solid phase micro-extraction also have a place. Analytical may employ GC-MS, GC-MS-MS, GC-MS/O, or other method appropriate to answer a specific question. If you need more information about how we can provide aroma support for new product development click HERE.

Odor Strategy Development

Strategies depend on variables such as the state of material (liquid, solid, gas), chemical type of suspected odorant (some chemicals must be treated different due to unique characteristics), quantity of material available, accuracy of odor descriptors, to name a few.

Based on answers to an initial questionnaire we will utilize the most appropriate and advanced scientific techniques and instruments currently available to detect and measure volatile chemicals responsible for odor. To find out more about our Odor Strategy Development service click HERE.

Odor Problems and Complaints

Burnt, solvent, glue, plastic, metallic, acrid, sharp are odor descriptors commonly used to describe the smell given off by some electronic components. If off-odor is a problem in one of your products, contact us. We design solutions to mitigate these type issues.